In practice, predictive maintenance means being able to analyze the condition of the equipment while using data and machine learning so that technicians can be notified about potential problems before a breakdown happens.

The aim of predictive maintenance technologies is to improve the way maintenance services are performed. Specifically, solutions and service recommendations can be made using real-time data from sensors and diagnostic tools inside the equipment. This process uses predictive maintenance software which determines when and why a failure might occur.

For example, a temperature sensor might detect that a component is running hot and trigger an immediate need for corrective maintenance. Or if it is not that serious, it can be repaired during regularly scheduled maintenance. Predictive maintenance increases safety, prevents issues and helps avoid the costs associated with a breakdown.

What is the difference between preventive and predictive maintenance?

The difference is that preventive maintenance uses expected life statistics to plan regularly scheduled maintenance intervals for equipment, while predictive maintenance uses data and the actual condition of the equipment to anticipate potential problems that can be proactively solved at the best possible time.

Predictive maintenance is unique because it uses real-time data from IoT sensors in the equipment to anticipate potential problems and costly failures. Additionally, it can automate some tasks, but more importantly, maintenance can be based on large sets of data which are continuously gathered around the clock.

If maintenance problems can be predicted, and a failure can be anticipated rather than just found during annual service, the saving in terms of cost and time are enormous.

What are the benefits of predictive maintenance?

The benefits of predictive maintenance are increased operational efficiency and the minimized down time that comes from a flexible maintenance schedule combined with the responsiveness of real-time equipment performance data analysis.

Predictive maintenance analytics offers:

- visibility into when an equipment problem is likely to occur

- asset management information which helps prolong equipment life

- equipment status updates notifying you of a problem

- flexibility to schedule maintenance at the most cost-effective time

- insight that improves inventory control for spare and wear parts

- verification that maintenance and repairs have been done correctly

Predictive maintenance IoT is important

For predictive maintenance to be effective, IoT sensors need to provide equipment data to the cloud where it is typically analyzed by machine learning algorithms.

Predictive maintenance uses IoT to generate terabytes of data and predictive maintenance software is required to turn data into actionable insights. Cloud computing power also has an important role to play. Specifically, the massive amount of data generated by IoT sensors must be processed efficiently in the cloud if issues are to be identified quickly.

IoT is a key part of detecting potential hazards and pinpointing when industrial equipment is likely to fail. It is on the front lines, acting like the “eyes and ears” of intelligent platforms that diagnose problems and propose solutions. This gives equipment owners peace of mind and more flexibility to plan and optimize equipment maintenance.

What are predictive maintenance tools?

There are three types of tools used in a predictive maintenance program:

- sensors and equipment diagnostics that generate data

- analytics tools that clean and process the data

- reporting and scheduling tools for performing maintenance

To track equipment performance, sensor technologies must be used to generate data which is processed by predictive maintenance software. The result is information and insights that are fed into reporting and scheduling tools where action is taken.

For example, a smartphone app uses predictive maintenance data to provide oversight and visibility that can lead to better decision making. But none of that is possible without the following predictive maintenance tools:

- IoT sensors

- Artificial intelligence

- Machine learning algorithms

- Cloud computing

- Data analytics software

Effective predictive maintenance services use all of these tools working together to predict equipment faults and optimize maintenance activities.

How can KONE help with predictive maintenance?

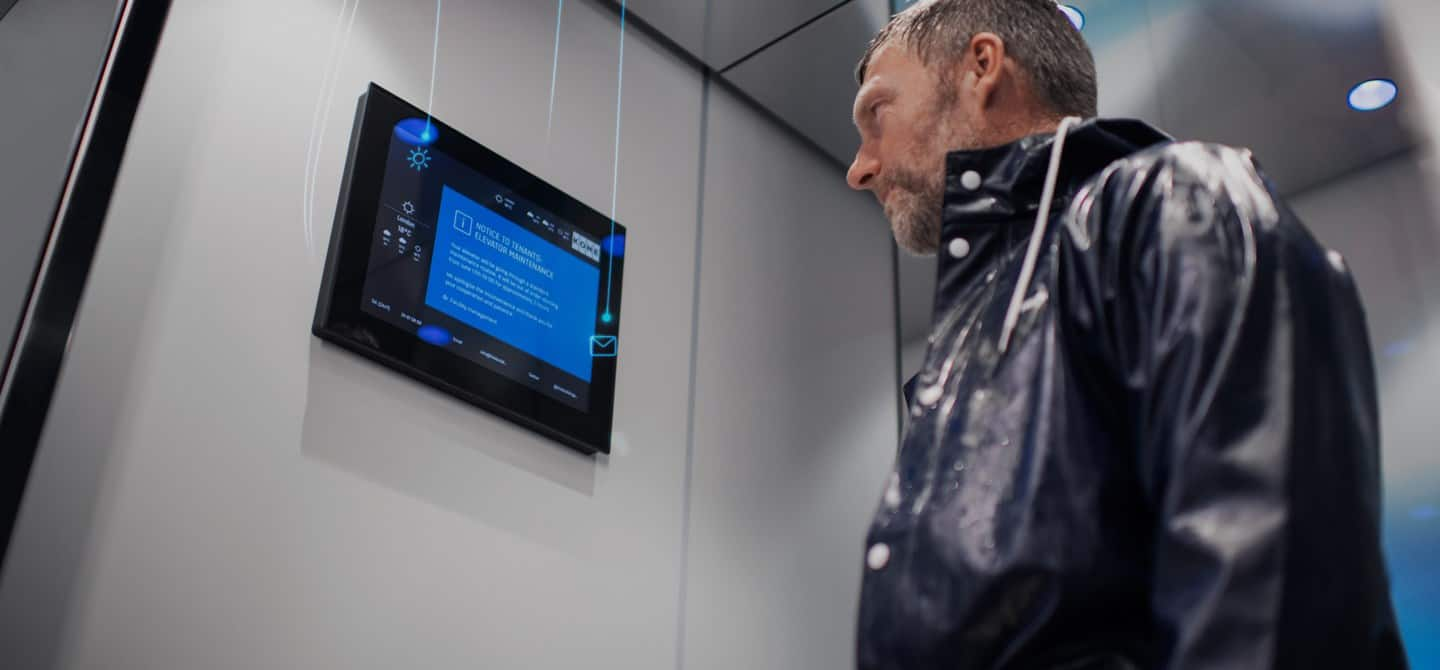

Predictive maintenance offers many benefits for building owners and facility managers. With its connected services, KONE uses advanced analytics to continuously monitor cloud data from elevators, escalators and automatic building doors. The data comes from sensors on the equipment and it gives insight into equipment condition and performance.

KONE predictive maintenance can determine if an issue must be addressed immediately or it if can wait until the next regularly scheduled maintenance. This offers building owners more flexibility and a more efficient approach to equipment maintenance.

One of the key benefits of KONE predictive maintenance services is data-driven recommendations for asset management and maintenance. For example, the KONE Online portal and the KONE Mobile app give access to performance, maintenance and repair data that helps facility managers make decisions.

KONE can help you make predictive maintenance a core part of your building operational model. Sensors, cloud capability, analytics software and other predictive maintenance tools can be part of new installations or can be retrofit to existing equipment.

Visit our predictive maintenance services page to learn more.